Molded pulp packaging machinery refers to the machines used to create molded pulp packaging products. Molded pulp is a type of packaging material made from paper or cardboard that has been treated with chemicals and heat to make it softer and more pliable. They are often used for products such as egg cartons, fruit trays, and coffee cups. The molded pulp packaging machinery used to create molded pulp packaging products typically includes a pulper, a molding machine, and a drying oven. The pulper breaks down the paper or cardboard into small pieces using water and chemicals. The molding machine then shapes the pulp into the desired shape. Finally, the drying oven dries the molded pulp product to make it ready for use.

3 molded pulp packaging machines

There are many different types of molded pulp packaging machinery available on the market today. Each type has its own advantages and disadvantages, so it is important to choose the right one for your needs.

1. Rotary molding machine

The rotary pulp molding machine is typically used for high-volume packaging applications and can significantly improve productivity in comparison to manual packaging methods. It is designed to fill and seal preformed containers with a variety of different products, such as juices, soups, sauces, and jams. The paper tray forming machine can also be used to package other items, such as laundry detergent and shampoo. The rotary pulp molding machine operates by filling a mold with pulp, which is then compressed and formed into the desired shape. The filled mold is then placed on a conveyor belt and transported to a seaming station, where it is sealed with a lid.

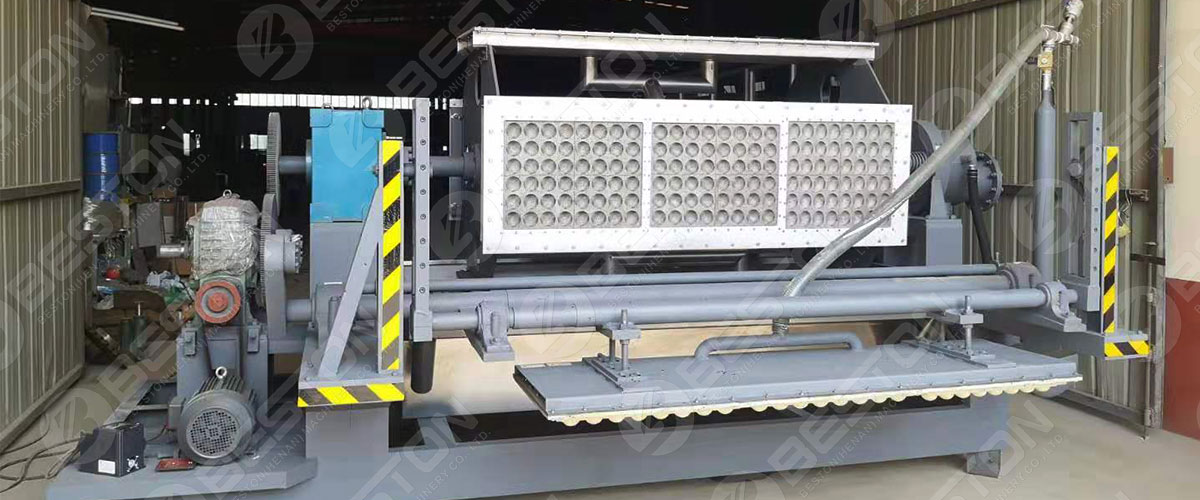

2. Reciprocating molding machine

A reciprocating pulp molding machine is a machine that is used to mold pulp into products such as egg cartons or drink coasters. The machine helps to evenly distribute the pulp and prevent it from sticking to the mold. It can be used with a variety of different pulp, including paper pulp, wood pulp, and even recycled pulp. The finished product can be customized to any size or shape, making it a versatile tool for any business. Reciprocating pulp molding machines are an essential part of the packaging industry and are used in a variety of industries, including food and beverage, cosmetics, and electronics: https://pulpmouldingmachines.com/egg-tray-manufacturing-machine/.

3. Web forming machine

A web forming molding machine can be used to form various types of items, such as paper, plastic, and metal. There are many different types of web-forming molding machines available on the market, each designed for a specific type of material. For example, some machines are designed for paper, while others are designed for plastic. Web forming molding machines can be either manual or automatic. Manual machines require the operator to feed the web-like material into the machine and then operate the machine to form the desired shape. Automatic machines, on the other hand, can automatically feed the material into the pulp molding machine and then operate the machine to form the desired shape.

In order to stay competitive in the market, it is important for businesses to research and invest in new technologies. Molded pulp packaging machinery is a recent technology that has the potential to revolutionize the packaging industry. Investing in it can provide high ROI if you can assess the demands for related packaging items in your state.