As you might imagine from the name , your wood charcoal machine can take wood scraps and transform them into a top-quality fuel perfect for fuel. Wood charcoal is one of the oldest sources of fuel known to man and has many uses, especially in the outdoor cooking sector. At present, the wood charcoal making machine has wide application in daily life.

Additionally, if you are connected to one of the many industries that produces considerable amount of waste in the form of wood, you will have a virtually unlimited supply of raw materials from which to begin large scale productions. If increasing your profits by transforming wood into a top quality charcoal is an interest of yours, read on to learn more about the process used by wood to charcoal machines

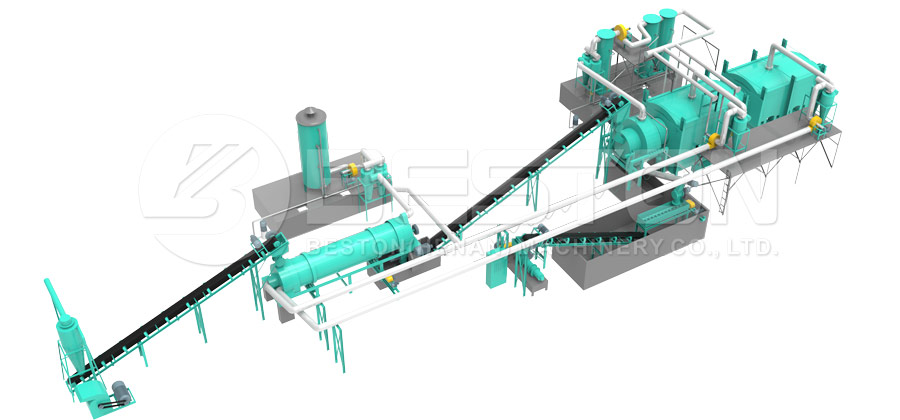

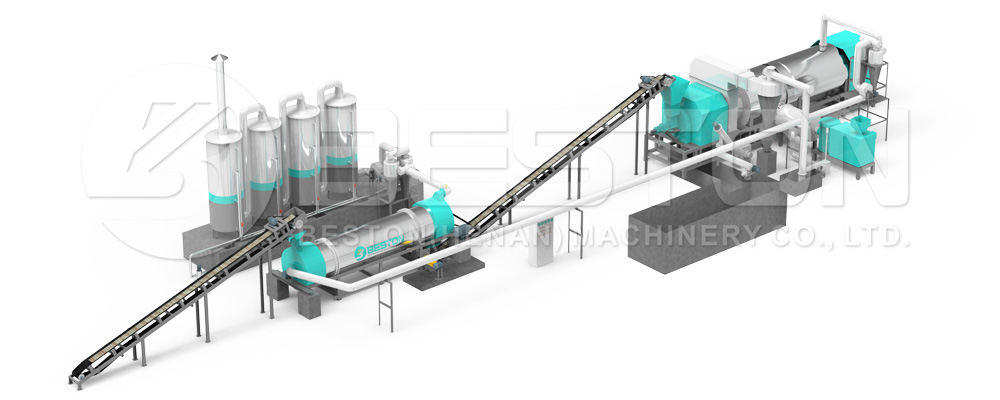

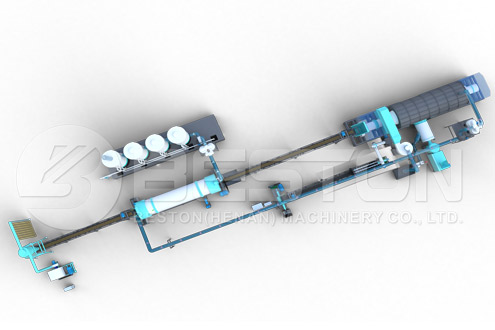

1. Carbonization Process of Wood Charcoal Machine

The first step is carbonization which improves the carbon value of the wood and take place in a carbonization furnace. Some of the more advanced machines for processing wood to carbon will accomplish this in two steps: drying and carbonization. Dry makes the wood more suitable to making charcoal from wood. Besides, if you wanna know the biochar kiln plans, get touch with the reliable manufacturer.

2. Recycling Combustible Waste Gas

The one problem with many wood to charcoal machines is the vast amounts of combustible gas collected in the machine. The best thing to do is to use a machine that has a plan to collect this gas and use it as a fuel to keep the char furnace burning. This improves the efficiency of the operations. Furthermore, some machines will have the capacity to extract valuable resins and wood vinegars in this process.

3. Dealing with the Smoke

The process of turning wood into charcoal will invariably begin producing a lot of smoke and heat. It is important to have a plan to process this as it can be a hazard to the environment and the staff in the workplace. Some components that a good wood charcoal machine will feature also collect dust and eliminate sulphur from the exhaust thus keeping the environment clean and healthy.

Choosing the Best Wood Charcoal Machine

If you are planning to invest in charcoal making machinery, you will want to keep some important points in mind, following are some key features to look for in a charcoal making machine.

1. No Residue and Reused Energy

This process is only ideal when there is no pollution and energy efficiency. You will find all you need to know on the good biochar pyrolysis equipment for you by reading the reviews and descriptions. Make sure you read the product specifics before choosing any machine that looks interesting.

2. Adequately Priced

It’s not always the most expensive that is the best option, be sure to calculate your capacity needs before choosing the machine that is best to suit them. Beware of poorly fabricated options though as they are not a good investment.

3. Top Quality of Wood Charcoal Machine

Take the time to research the best manufacturers of the machines you are looking for. The higher the quality and better the materials the longer your charcoal making machine will last and the more profits you can expect to make. Click components of charcoal making machine for the top one.