It is amazing how environmental wastes can be turned into treasure. Increasing environmental concerns have led to the development of technologies that help in recycling wastes into useful end products. This includes the development of biochar production equipment that recycles organic wastes such as wood. Sawdust, coconut shells and rice husks by the process of pyrolysis to produce biochar, a product that has great importance in the agricultural and environmental sector.

Biochar production equipment employs the principle of carbonization whereby the biomass material is heated at very high temperatures in the absence of oxygen to produce the final product biochar and other important products such as bio-oil, biogas and charcoal which are eco-friendly sources of energy.

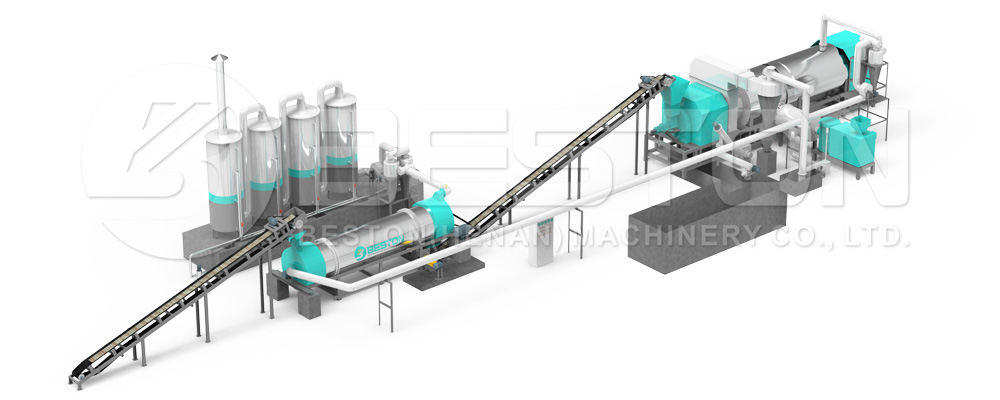

Main components of a bio char production equipment

•A reactor that is used to heat up the raw materials for biochar production.

•A crushing system that breaks down the raw materials into the required size of 50mm.

•The casing that protects the furnace by insulating it and thus prevent loss of heat during the carbonization process.

•A conveyor that directs the dried raw materials into the furnace.

•A drier system that is used to dry the raw material to reduce their water content and thus increase the efficiency of the machine.

•A condenser that is used to cool oil and gas produced during the process of biochar production.

•Hydro seal system that is used to remove impurities from the gas produced during the process.

•An automated discharge system for emptying the final product from the machine. More information on biomass pyrolysis plant here.

Working process of a biochar production equipment

The raw materials which include sawdust, rice husks and wood, using the crushing system are crushed down to the size of 50mm. the materials are then conveyed into the drying system where they are dried to a moisture content of less than 20%. From the drying section, the materials are conveyed into the reactor where they undergo carbonization at high temperatures with no oxygen. At a temperature of 100 degrees, the raw materials will produce combustible gas which will be piped into the hydro seal system where it will be purified by removing sulphur. The gas is then directed into the condensing system where it will be cooled allowing for the removal of tar and wood vinegar. The remaining gas is then channelled back to the reactor where it is used as fuel. The remaining product of charcoal and biochar is cooled by the cooling system and then collected via the discharge system.

Factors to take into consideration during the production process

1.The water content of the raw material.

The water content of the feedstock should be below 20% in order to obtain quality end products. Raw materials with a higher amount of water are required to undergo drying before they are fed into the reactor.

2.Chemical composition of the feedstock

The quality of biochar produced varies considerably in terms of the physiochemical properties depending on the contents of the raw materials.

Raw material containing a high content of cellulose, hemicellulose and lignin is required for high quality and yield of biochar and thus using feedstock from agricultural waste is highly recommended.

3.Operating temperature and heating rate.

The chemical composition of biochar is highly affected by the temperature on which carbonization is taking place. At very high temperatures, the oxygen and hydrogen levels are diminished with increasing levels of carbon content. This results in the increase in the PH of biochar making it unsuitable for agricultural purposes.

4.Vapour residence time

It is advised that the charcoal making equipment to remain closed to allow polymerization of the vapours produced which will, in turn, increase the quality of biochar.

Various applications of biochar

•Application of biochar into the soil increases the capacity of the soil to retain nutrients such as phosphorus and nitrogen which could otherwise be leached into the water systems causing pollution.

•Addition of biochar into the soil increases the crop production yield by adding nutrients into the soil.

•Biochar aids in conserving the environment by protecting it from pollution since it uses organic contaminants from the environment as a raw material.

•Biochar acts as a soil conditioner where it increases the water holding capacity of the soil.

Uses of other products that are obtained during biochar production include

•Charcoal is used as a biofuel.

•Wood vinegar is used in chemical industries for the preservation of food.

•Biogas is also used as a source of fuel.

Advantages of biochar production equipment

i.It is efficient and does not require a lot of labour to operate.

ii.Quality of the final products is considerably high.

iii.It provides a conducive environment to work on due to the presence of a casing that provides insulation.

iv.It is closed and hence does not allow air to get in and thus high-quality products and also prevent accidents caused by the presence of air in the reactor.

v.Excess gas is channelled back to the reactor where it can be reused and thus conserve energy. Get high-quality rice husk carbonizer here.