Amidst the global call for carbon reduction and sustainable practices, the role of charcoal maker machines has transcended its traditional identity. Beyond being a tool for fuel production, these machines have emerged as key players in carbon storage, contributing to the vital cause of mitigating climate change. In this post, we delve into the synergy between charcoal maker machine and carbon storage, shedding light on their transformative impact on the environment.

Charcoal Maker Machines: Beyond Fuel Production:

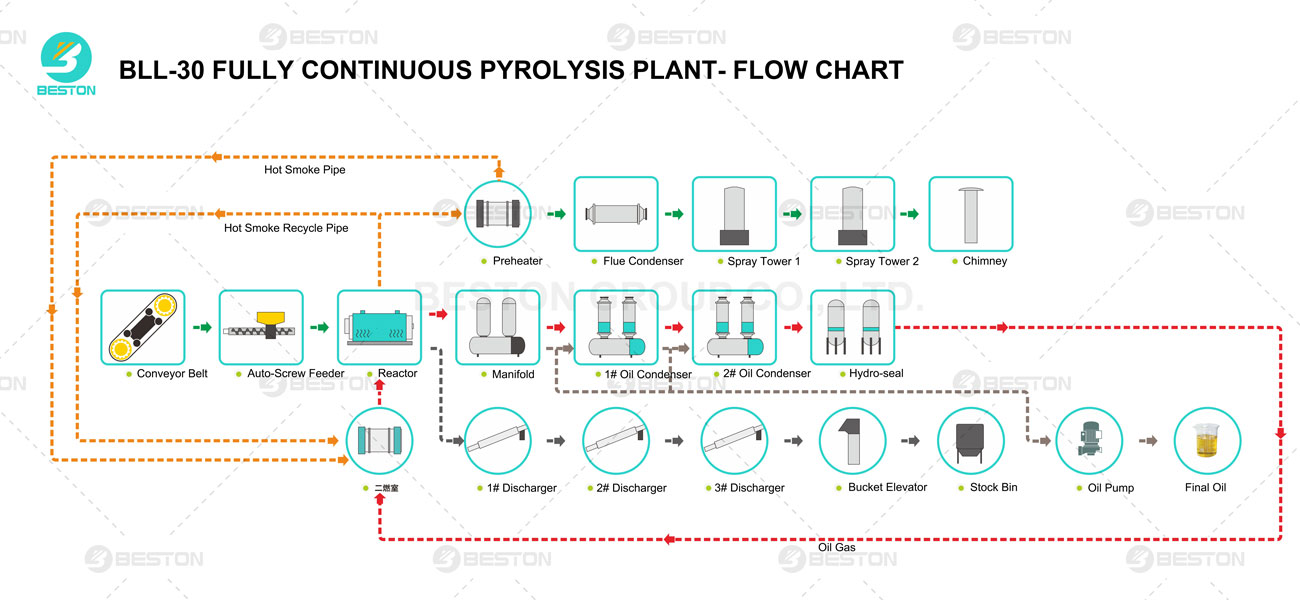

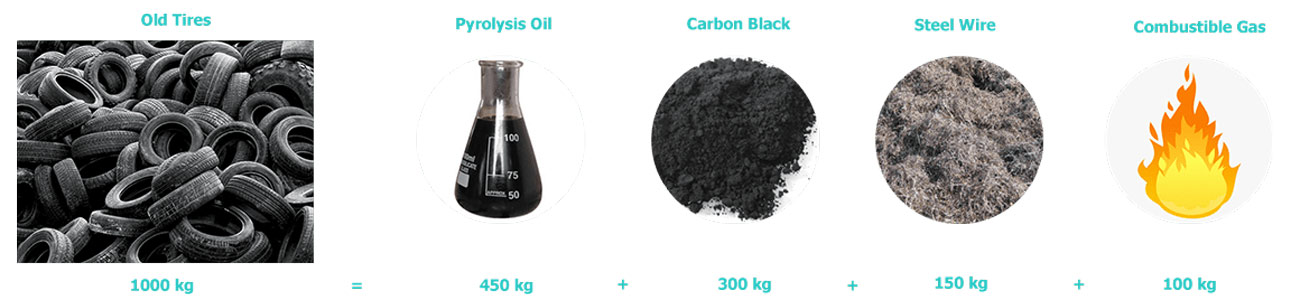

Charcoal maker machines are designed to convert organic biomass materials into charcoal through a process known as pyrolysis. This innovative technology not only addresses waste management but also facilitates the creation of charcoal—a carbon-rich material that holds the potential for carbon storage.

Unlocking Carbon Storage Potential:

Carbon Sequestration: Charcoal, produced by Beston mobile biochar machine, possesses the ability to sequester carbon. When incorporated into soil, charcoal acts as a stable reservoir for carbon, mitigating the release of carbon dioxide (CO2) into the atmosphere.

Long-Term Carbon Retention: Unlike some other carbon storage methods, charcoal remains intact in soils for centuries, ensuring long-term carbon retention and contributing to climate stability.

Soil Health Enhancement: Charcoal’s presence in soil enhances its structure, water-holding capacity, and nutrient retention. This boosts plant growth, further aiding in carbon capture through photosynthesis.

The Carbon Storage Imperative:

Carbon storage is not merely an environmental luxury; it is an urgent necessity. As CO2 levels rise and climate impacts intensify, the need to explore innovative solutions becomes paramount. Charcoal maker machines step into this narrative as agents of change, offering a unique approach to carbon storage that aligns with sustainable practices.

Sustainable Synergy: Charcoal Maker Machines and Carbon Storage:

Waste-to-Resource Transformation: Charcoal maker machines repurpose biomass waste, preventing its decay and the associated release of CO2 and methane—a potent greenhouse gas.

Soil Enrichment: The integration of charcoal into soil improves its fertility and water retention, fostering healthier vegetation that plays a pivotal role in carbon capture.

Circular Economy Contribution: The outputs of charcoal maker machines—charcoal and biochar—can be cycled back into agricultural systems, closing the loop and promoting sustainability. This page may help investors to get large-capacity machines: https://www.bestongroup.com/biochar-making-machine/.

Towards a Carbon-Responsible Future:

The convergence of charcoal maker machines and carbon storage signifies a new era of carbon-conscious practices. It reflects the potential of technology to address pressing environmental concerns while fostering economic growth. As we navigate the complexities of climate change, these machines stand as beacons of hope, offering a path towards carbon storage and environmental resilience.

Charcoal maker machines, once seen solely as instruments for fuel, now emerge as catalysts for positive change. Their ability to generate charcoal, while concurrently contributing to carbon storage, positions them as indispensable tools in the global effort to combat climate change. Through innovation, commitment, and the recognition of the intertwined nature of sustainability and progress, we embark on a journey towards a carbon-responsible future—one that embraces the power of charcoal maker machines to foster carbon storage, environmental restoration, and a more resilient planet.