Pyrolysis devices, an important energy conversion technology, offer potential opportunities for renewable energy and chemical production by decomposing organic matter into gas- and liquid-phase products at high temperatures. The analysis and utilization of gas-phase and liquid-phase products produced in pyrolysis plants has important application potential. By accurately analyzing and understanding the composition and properties of the products, we can optimize the pyrolysis process and apply the products in the production of renewable energy and chemicals.

Analysis and Utilization of Gas Phase Products

Analytical method

Gas phase products produced by pyrolysis equipment typically include gases and volatile organic compounds (VOCs). Accurate analysis of gas phase products is the key to evaluating the effect of the pyrolysis process and optimizing reaction conditions. Common analytical methods include mass spectrometry, gas chromatography, and infrared spectroscopy. These methods can help to determine the species, concentration, and composition of products to further optimize the pyrolysis process.

Field of use

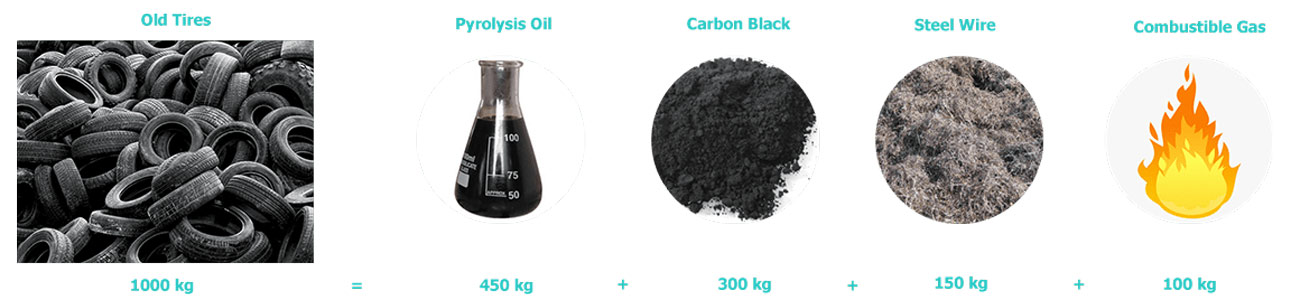

- Fuel production: Combustible gases in gas phase products, such as hydrogen, carbon monoxide and methane, can be used as fuels to replace petroleum. These gases can be collected, purified and stored for use in electricity generation, heating or as a chemical feedstock.

- Chemical synthesis: VOCs in gas phase products can be used as raw materials for organic synthesis. For example, acetic acid, alcohols, and ketones are used in the production of chemicals such as solvents, paints, and plastics.

Analysis and Utilization of Liquid Phase Products

Analytical method

Liquid phase products typically include liquid oil and water that are processed by waste oil distillation plant. Analyzing the composition and properties of liquid phase products is crucial for optimizing the pyrolysis process and developing high value-added products. Common analytical methods include gas chromatography, liquid chromatography, and mass spectrometry. These methods can reveal the composition, content and physicochemical properties of liquid phase products.

Field of use

- Biofuel production: Combustible components in liquid phase oils can be extracted and converted into biofuels, such as biodiesel and bioliquid fuels. These biofuels can be used in transportation and industry, reducing dependence on traditional petroleum fuels.

- Chemical production: Organic matter in liquid phase products can be used to synthesize various chemicals, such as lubricants, oils, coatings and additives. These chemicals can meet the needs of different industries and contribute to the development of a sustainable chemical industry.

Continuous Improvement and Development

The analysis and utilization of gas and liquid phase products in pyrolysis reactor is a field of continuous development and improvement. As technology advances, new analytical methods and exploits continue to emerge. At the same time, it is also necessary to strengthen the research on the relationship between product characteristics and performance, so as to further improve the quality and utilization efficiency of the product.

The analysis and utilization of gas-phase and liquid-phase products produced in pyrolysis plants has important application potential. By accurately analyzing and understanding the composition and properties of the products, we can optimize the pyrolysis process and apply the products in the production of renewable energy and chemicals. With the continuous development of technology, pyrolysis equipment is expected to become an important tool for sustainable energy conversion and chemical production, promoting the development of an environmentally friendly economy.

You can visit Beston Group to know more about pyrolysis plant and its products.