The wood charcoal making machine is typically useful in converting the wood into biochar. With this kind of material, it can help produce not only the mosquito-repellent incense but also barbecue carbon. Furthermore, bio charcoal has numerous applications in industries of rubber, paint, ink, and so on.

Why Should You Invest in a Wood Charcoal Making Machine?

– If you use wood chips with the wood charcoal making machine, it will not produce any residue since there are neither chemicals nor additives in the wood charcoal making process. Also, its products have no waste. Even with the smallest scale, you’ll gain more profits with these charcoal machines.

– The charcoal will not produce the waste liquid since it doesn’t require water in the entire production process. What’s more, it will neither cause water pollution nor waste liquid.

– If you use wood to make charcoal, it will not emit waste gas. Nearly every production part can generate steam and a relatively small percentage of combustible gas. Wood carbonization machine, therefore, has no air pollution.

What Are the Features of the Wood Charcoal Making Machine for Sale?

So, how do you use wood to make charcoal? The wood charcoal manufacturing equipment sticks to the operation principle that prioritizes on integrity and quality. The plant also has a unique structure and adopts advanced technology, which can greatly enhance the quality of products. Click here to know more about the sawdust charcoal making machine here.

For instance, due to the varying lengths and shapes of wood, the wood charcoal making machine comes with a crusher that can help in making the wood materials to carbonize uniformly. Additionally, as opposed to other machines, the wood carbonization machine only needs considerably low investment but has a high output, continuous and fast carbonized production structure.

As a result, one side can deal with feeding while the other is discharging, saving more time and being more efficient. What’s even more appealing about these machines is that they’re automated, which reduces both the workforce and cost. Since the machine has a unique and reasonable design, is easy to operate, has a small size, and covers a relatively small floor area, all of these features can provide clients with significantly higher economic benefits. Check out the palm kernel shell charcoal making machine here.

The Wood Carbonization Plant’s Unique Structure

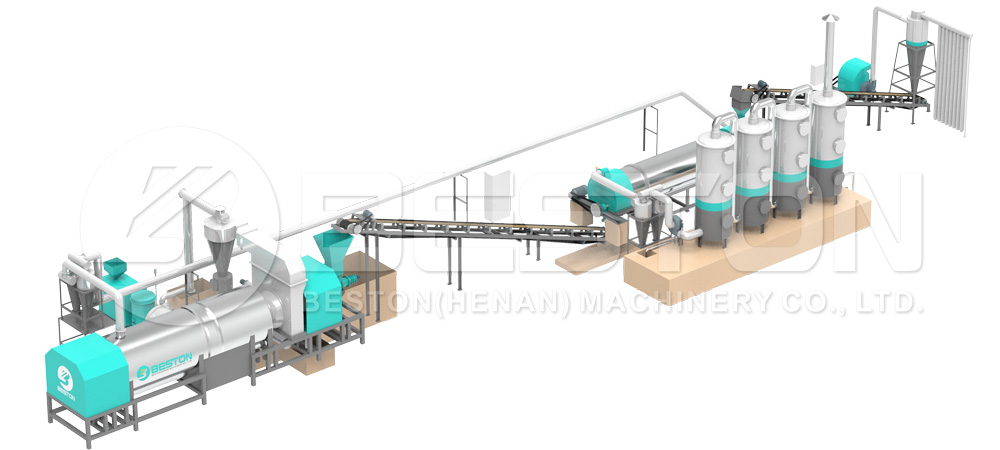

The carbonization of wood adopts a unique structure, which mainly consists of the fist-class pretreatment device that is basically drying, carbonization furnace, as well as other supporting plants, which includes a feeding system, dedusting system, discharge device, cooling system, rack part, and a drive system.

The unique structure of the wood manufacturing equipment can make the materials to make contact with the heat source for roughly three times, thus increasing the heat utilization efficiency and saving the energy. When it comes to the biochar production equipment, the coconut charcoal making machine is also a part, which includes two main parts.

These are the wood carbonization furnace and the dedusting system. The former has the fuel gas recycling furnace and the warming chamber and can reuse the CO to lower the air pollution and meet the emission standard. The latter comprises three filters that clean and purify the tail gas.