Plastic Pyrolysis Plants represent a pivotal solution in the contemporary battle against the escalating plastic pollution crisis. As the world grapples with the consequences of excessive plastic consumption and disposal, these innovative facilities have emerged as a beacon of hope. This article delves into the multifaceted benefits of plastic pyrolysis plants, offering a comprehensive exploration of their environmental, economic, and technological advantages.

Environmental Benefits

In the realm of environmental preservation, plastic pyrolysis plants stand as formidable allies:

1. Reduction of Plastic Pollution

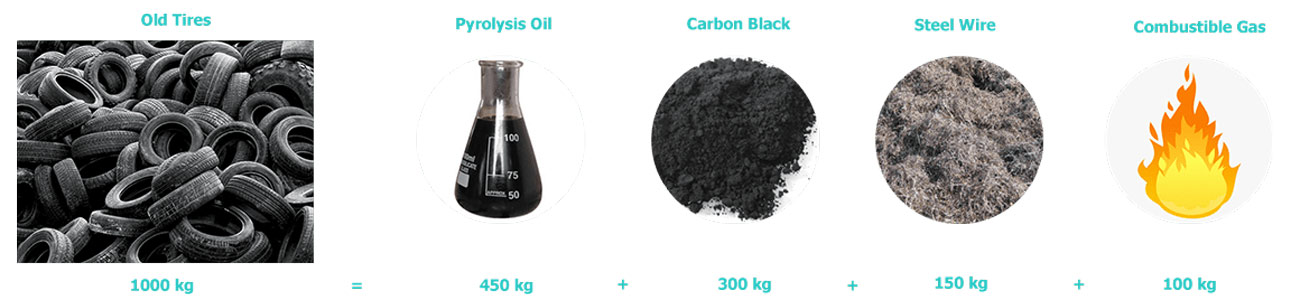

Plagued by plastic litter and oceanic waste patches, the planet yearns for solutions that can alleviate its plastic woes. Plastic pyrolysis plant excels in this regard, converting discarded plastic waste into valuable products such as oil, gas, and carbon black. By doing so, they diminish the volume of plastic entering landfills and water bodies.

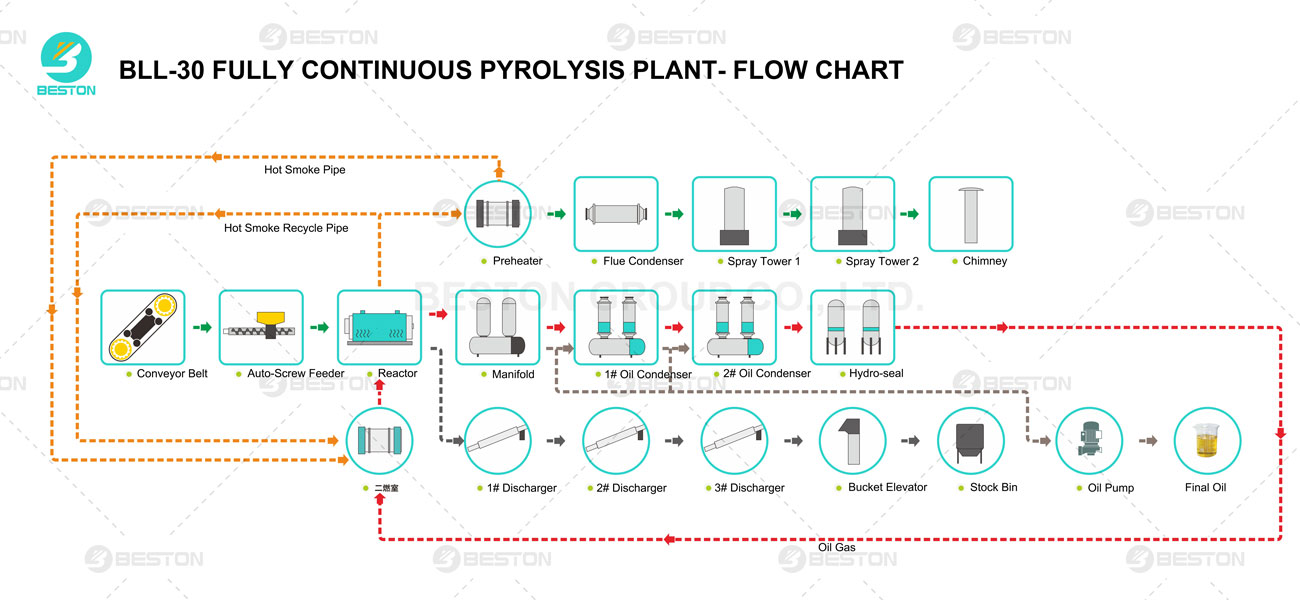

The process begins by feeding plastic waste into a high-temperature reactor, where it is subjected to intense heat in an oxygen-starved environment. This results in the breakdown of plastics into their constituent hydrocarbons, effectively eradicating the waste at its source.

2. Lower Greenhouse Gas Emissions

Traditional plastic incineration emits harmful greenhouse gases, exacerbating climate change. In contrast, plastic pyrolysis is a significantly cleaner process. The absence of oxygen during pyrolysis prevents the formation of harmful by-products like dioxins and furans. As a result, these plants contribute to reduced carbon footprints, aligning with global efforts to combat climate change.

3. Energy Recovery

Beyond waste reduction, plastic pyrolysis plants offer a unique opportunity for energy recovery. The process yields valuable hydrocarbon-based products, including pyrolysis oil, which can be further refined into fuels like diesel and gasoline. This resourceful aspect not only reduces the demand for virgin fossil fuels but also bolsters energy independence.

Economic Advantages

The economic viability of plastic pyrolysis plants extends across various dimensions:

1. Resource Efficiency and Circular Economy

A pyrolysis machine exemplifies resource efficiency by extracting maximum value from discarded plastic materials. This aligns with the principles of a circular economy, where products and materials are recycled, repurposed, or transformed to minimize waste and maximize utility. The recovered products can be used in various industries, fostering resource sustainability.

2. Job Creation

The establishment and operation of plastic pyrolysis plants create employment opportunities across a spectrum of roles, from plant technicians to researchers developing advanced pyrolysis technologies. This is particularly vital in regions grappling with unemployment and underemployment.

3. Revenue from By-Products

The by-products of plastic pyrolysis, such as carbon black and steel wires, can be sold as valuable commodities. This adds an additional revenue stream to the business model of pyrolysis plants, making them financially appealing investments.

Technological Advancements

The evolution of plastic pyrolysis technology continues to drive its efficacy:

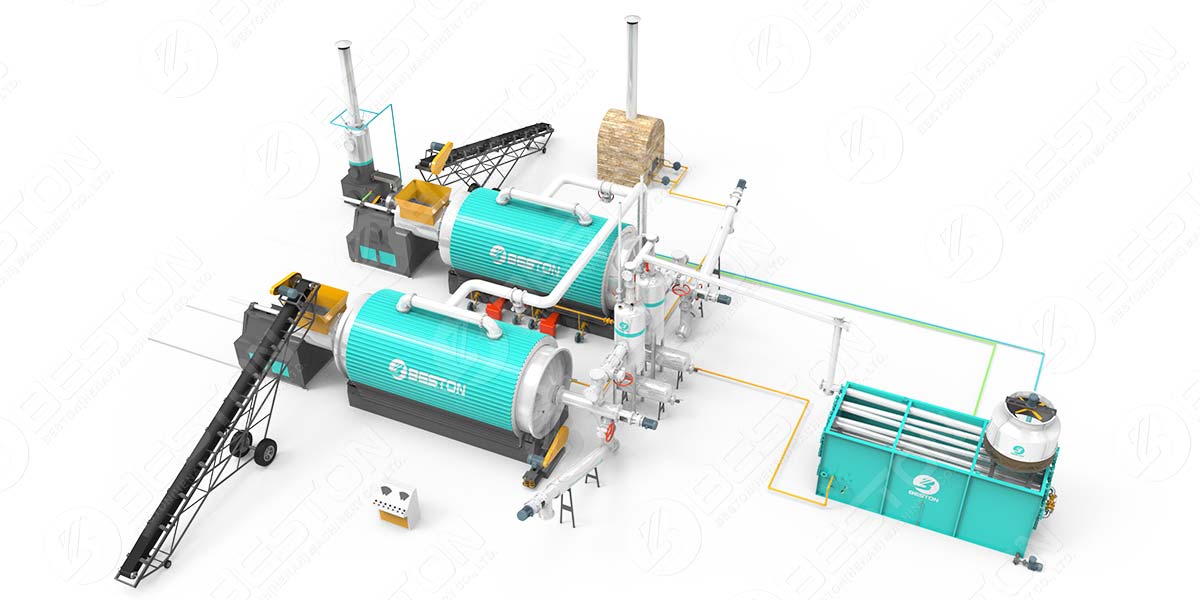

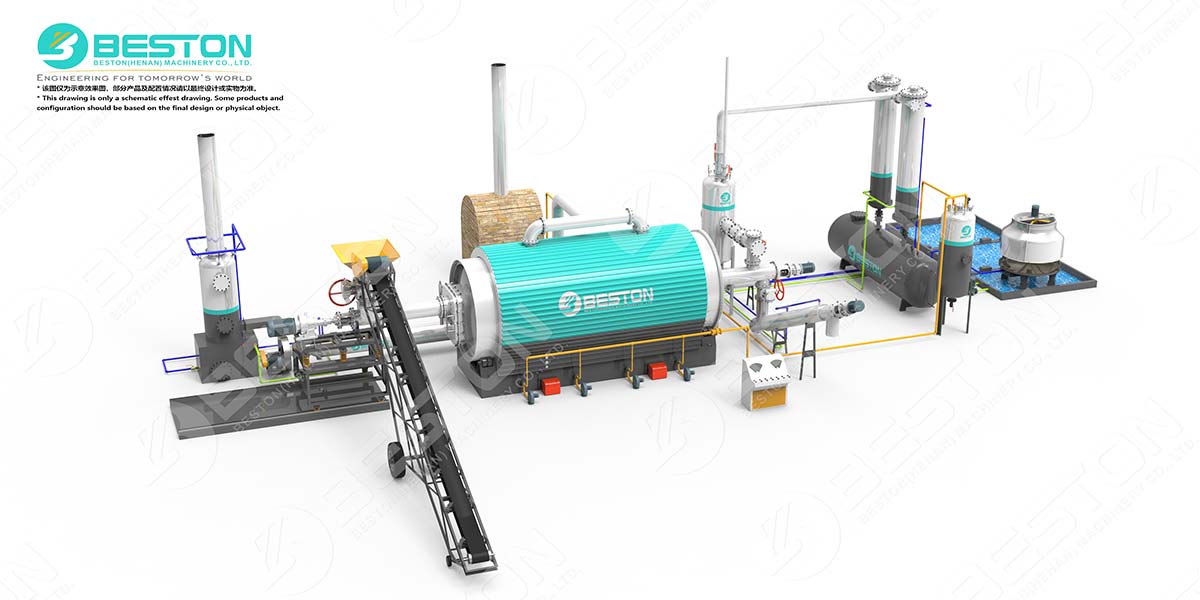

1. Continuous vs. Batch Pyrolysis Systems

Recent advancements have led to the development of continuous pyrolysis systems, which offer higher efficiency and productivity compared to small pyrolysis machines. These continuous systems allow for a steady input of plastic waste, resulting in a continuous output of valuable products.

2. Catalytic Pyrolysis for Enhanced Yields

Catalytic pyrolysis introduces catalysts into the process, which accelerate the breakdown of plastics and enhance the yield of high-value products like gasoline and diesel. This innovation has the potential to further improve the economic viability of plastic pyrolysis plants.

3. Integration with Existing Facilities

Some industries are exploring the integration of plastic pyrolysis plants with their existing facilities to manage plastic waste generated during their processes. This synergistic approach minimizes waste disposal costs and enhances sustainability.

Future Prospects and Conclusion

Plastic pyrolysis plants, with their compelling environmental, economic, and technological advantages, hold immense promise for addressing the plastic pollution crisis. As the world pivots towards sustainable plastic management, the global adoption of pyrolysis technology is poised to grow. These plants symbolize a conscientious step towards a cleaner, more sustainable future, where plastic waste is transformed into opportunities for environmental conservation and economic prosperity. If you want to obtain professional technical services, you can consult Beston Group. This is an experienced producer that you can consult at: https://bestonasia.com/