The disposal of scrap tyres has long presented environmental and economic challenges. Traditional methods such as landfilling and incineration are unsustainable and pose significant risks to both ecosystems and human health. In contrast, pyrolysis recycling offers a profitable and environmentally friendly solution. The process involves the thermal degradation of tyres in an oxygen-free environment, breaking them down into valuable by-products. This article explores the economic value of pyrolysis recycling, particularly focusing on the role of a tyre pyrolysis plant.

Overview of Pyrolysis Recycling

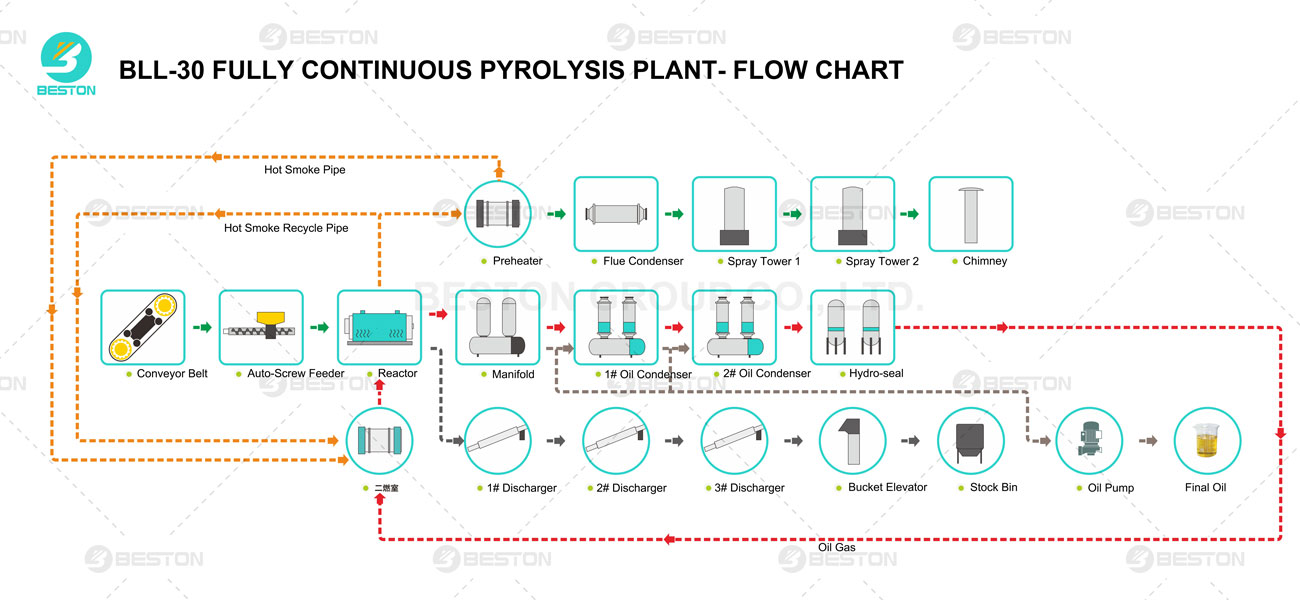

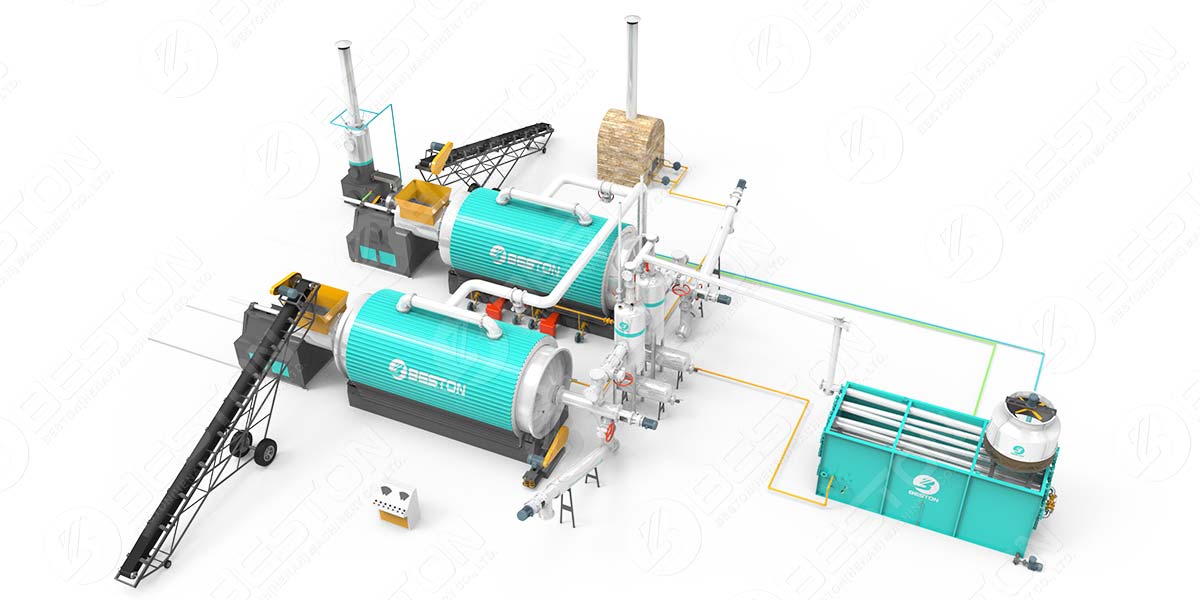

Pyrolysis is a chemical process that decomposes organic materials at elevated temperatures without oxygen. In the context of scrap tyres, the process breaks down complex rubber compounds into simpler forms. A tyre pyrolysis plant is equipped to handle this process, converting tyres into various marketable products.

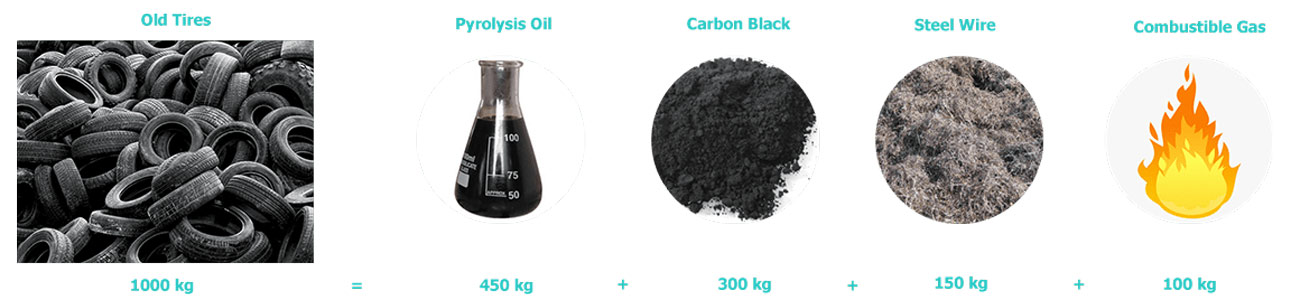

During pyrolysis, scrap tyres are heated in a reactor, where they undergo thermal decomposition. The result is the production of several valuable outputs:

- Pyrolysis oil: A liquid fuel that can be used as an alternative to diesel or further refined.

- Carbon black: A fine powder that serves as a reinforcing agent in rubber products and a pigment in various industries.

- Steel wire: Recovered from the steel belts within tyres, which can be recycled for industrial use.

- Synthesis gas: A gas mixture that can be used as an energy source for powering the pyrolysis plant itself or other industrial processes.

These by-products offer significant economic opportunities, making tyre pyrolysis not only an environmentally sound method but also a profitable venture.

Cost-Effective Waste Management

The most immediate economic advantage of a tyre pyrolysis plant is the reduction in waste disposal costs. Traditional methods such as landfilling or incineration incur high fees and are subject to increasingly stringent environmental regulations. By contrast, pyrolysis allows for the recycling of tyres while generating revenue from the sale of by-products.

Furthermore, the establishment of a tyre pyrolysis plant can reduce dependence on landfills, which are becoming increasingly scarce and expensive to maintain. This makes pyrolysis an attractive option for municipalities and waste management companies seeking sustainable waste disposal alternatives.

Revenue Generation from By-Products

A key factor driving the economic viability of tire to fuel plant is the market demand for the resulting by-products. Each of these materials can be sold or reused, creating multiple streams of income.

- Pyrolysis Oil: One of the most valuable by-products, pyrolysis oil can be used directly as a fuel in industrial applications or further refined into high-quality diesel. This flexibility makes it highly sought after in markets where alternative fuels are in demand.

- Carbon Black: The recovery of carbon black presents an opportunity to tap into the lucrative rubber and plastics industries. It can be used in the manufacture of new tyres, inks, coatings, and plastics, reducing the need for virgin carbon black, which is both costly and environmentally damaging to produce.

- Steel Wire: The steel recovered from tyres can be sold as scrap metal. While not as high in value as other by-products, it still contributes to the overall profitability of the process by providing a consistent and recyclable material.

- Synthesis Gas: The synthesis gas produced during pyrolysis can be captured and used to power the tyre pyrolysis plant itself, reducing energy costs. In some cases, excess gas can be sold or used for other industrial purposes, adding another layer of economic benefit.

Job Creation and Local Economic Stimulation

The operation of a tyre pyrolysis plant creates direct and indirect job opportunities. From plant workers and engineers to transport and sales staff, the establishment of a pyrolysis facility contributes to local employment. This is particularly beneficial in regions where traditional industries are in decline or where unemployment rates are high.

Moreover, the economic activity generated by a tyre pyrolysis plant has a multiplier effect on local economies. Supporting industries, such as logistics, machinery maintenance, and waste collection, also benefit from the presence of a pyrolysis facility. In many cases, local governments provide incentives or subsidies for the establishment of such plants, further enhancing their economic impact.

Sustainable Business Model

A rubber pyrolysis plant not only presents a profitable business opportunity but also aligns with the growing global focus on sustainability and circular economy principles. Companies and governments are increasingly recognizing the importance of reducing waste and reusing materials. Pyrolysis recycling fits into this paradigm by transforming a waste product into valuable resources, reducing the reliance on raw materials.

Additionally, the environmental benefits of pyrolysis, such as the reduction of greenhouse gas emissions compared to traditional disposal methods, can lead to further economic advantages. Companies operating pyrolysis plants may qualify for carbon credits or other incentives tied to sustainable practices. This opens the door to additional revenue streams that can enhance the overall profitability of the plant.

Addressing Market Demand for Recycled Materials

The market for recycled materials is growing rapidly, driven by both regulatory pressure and consumer demand for sustainable products. Tyre pyrolysis fits into this trend by providing a source of high-quality recycled materials, such as pyrolysis oil and carbon black. Industries that rely heavily on these materials, such as rubber manufacturers and fuel producers, are increasingly looking for sustainable alternatives to virgin resources. A tyre pyrolysis plant can meet this demand, positioning itself as a key player in the recycled materials market.

Moreover, as regulations around the disposal of scrap tyres become more stringent, the demand for environmentally friendly recycling solutions is expected to rise. A tyre pyrolysis plant offers a solution that not only meets regulatory requirements but also provides an economic return on investment. This creates a compelling business case for companies and municipalities looking to address their tyre waste problems.

Long-Term Profitability

While the initial investment in a tyre pyrolysis plant can be significant, the long-term economic benefits often outweigh the costs. The sale of by-products, combined with the reduction in waste management fees, creates a sustainable revenue model. Additionally, advancements in pyrolysis technology are continuously improving the efficiency and scalability of the process, making it more accessible to a broader range of businesses. If you have any questions about the benefits of tire pyrolysis projects, please contact Beston Group China.

The ability to produce valuable materials from a waste product also insulates the business from fluctuations in raw material costs. As the prices for oil, carbon black, and other industrial inputs continue to rise, the use of recycled materials from pyrolysis offers a cost-effective alternative.

Conclusion

The economic value of pyrolysis recycling of scrap tyres is clear. A tyre pyrolysis plant not only provides an environmentally sustainable solution to the global tyre waste problem but also generates significant revenue through the sale of by-products. With the growing demand for recycled materials and the need for more sustainable waste management practices, tyre pyrolysis is poised to become an essential component of the modern circular economy. The economic, environmental, and social benefits make pyrolysis recycling a smart investment for businesses and governments alike.