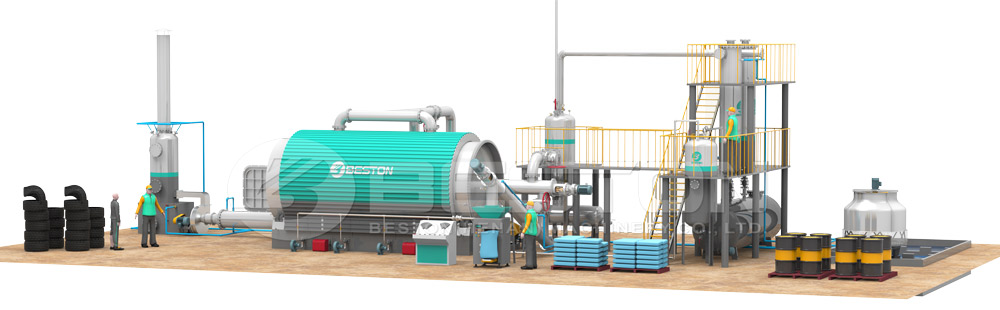

When pyrolysis machines and plants were first manufactured, they did not have a very strong following. However, environmental changes that made it necessary to invest money in products that can help us with current problems we are all facing. One of those includes rubber tyres. There are billions of them located worldwide. In most cases, these cannot be used for any reason until they are processed. One of the best ways to do so is by using a scrap tyre pyrolysis plant. The cost of these can be quite expensive yet there are ways that you can save money.

How Much Do They Cost?

If you are getting an entire waste tyre pyrolysis plant, you are likely going to spend six figures or more on this type of investment. However, it can pay for itself many times over if you have an ample supply of rubber tyres to work with. For example, if you have a landfill at your disposal, and can use those tyres, you can begin to make a profit from this in a short period of time. Additionally, if you have a municipal solid waste company that is receiving rubber tyres daily, you can process these instead of having to pay for their disposal. Get tyre pyrolysis plant cost here.

Why Are These A Good Investment?

These are very good investment for two reasons. First of all, if you do have to pay for the disposal of rubber tyres, you are going to save money by converting them into burnable fuel. Second, the more that you convert, the more of the charcoal and biofuel that you can sell to those that will pay top dollar. This is a very popular type of fuel that is used worldwide which is why a waste tyre recycling plant will be a very good investment. You do need to find a seller that is reputable, and also offers all of their products at the lowest prices possible.

Locating The Best Manufacturer

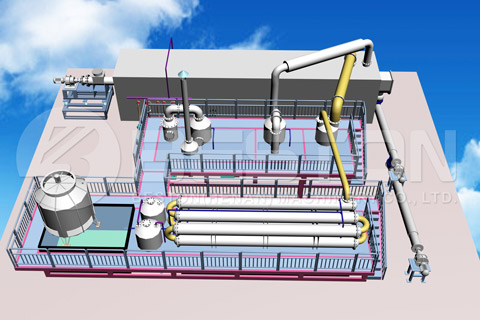

You can easily locate a manufacturer that can help you out. You can speak with them directly or send them a text message. Once you have an estimate on the total cost of the pyrolysis plant that you would prefer purchasing, you can then make the decision to obtain it. Make sure that you have a place for it at your facility. These tend to be very large in size. Once it is fully functional, you will soon have the ability to sell the bio oil, biofuel, and the charcoal you will be able to produce.

Waste tyre recycling plant for sale can be costly. By searching online for manufacturers that produce these annually, you will find one that is in your price range. Many of these are designed for converting millions of tyres every year, depending upon their size and consistency. As you begin to create more of the biofuel and charcoal, you will soon have more customers coming to purchase these materials from you. It’s a great investment to make, and one that will not only be profitable, but also one that can improve the environment by eliminating rubber tyres that would simply go to waste.