Pyrolysis is a method of creating a chemical reaction that breaks down larger molecules of any organic waste material into smaller ones through the application of heat. Temperatures of between 400 and 500 degrees are maintained in the absence of any oxygen for starting the burning. This method has been found very useful in burning waste tires that would have otherwise found their way into landfills that would add to environmental damage.

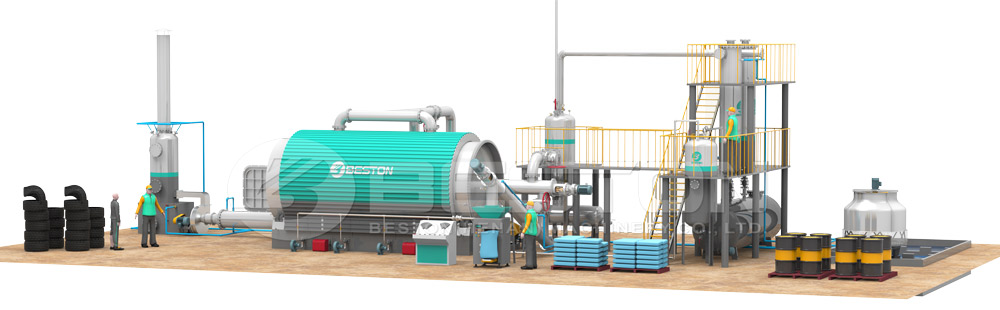

A waste tyre to oil plant converts useless tires that have outlived their utility, into industrial fuels oils and also produces carbon black, steel wire, and hydrocarbon gas. Different ratios of oil become available after the pyrolysis, all of which find their use in several industrial applications, like glass, steel manufacture, ceramics, and iron. A waste tire will turn into 45 percent oil, 30 percent carbon, 10 percent gas, and produce 15 percent of steel during the process of pyrolysis.

The tire oil produced during pyrolysis can be used as industrial fuel for burning, or further refined to be converted into diesel or gasoline in a distillation plant. The oil produced from waste tires is often used in generators for the production of electricity. It can also be directly marketed as a fuel or even be partly used in the pyrolysis plant itself to fuel the pyrolysis reactor.

Carbon black produced in these plants is often used in the construction of bricks with clay or it can also be used as a fuel. It can be produced into carbon black that has many other industrial uses. For making it into fuel, this carbon will be made into pellets or used as a basic material for making pipes and cable jackets. Click here to know more: https://bestonpyrolysisplant.com/.

Waste tires, especially the radial types, contain a fair amount of steel, and this steel can be recovered from the waste tires and sold directly to recyclers or processed further. The pyrolysis process also produces combustible gas that is often recycled back into the furnace of the reactor to heat it or can be stored separately for use as fuel.

Most pyrolysis plants work on automatic or semi-automatic processes that make them easy to run and require the least attention other than ensuring that they are properly fed with the waste material. The waste tire recycling equipment is equally capable of converting waste plastic into an oil as well, thus making them fairly versatile. They often come equipped with shredders that help in removing the steel, as well as allow for even heating of the material due to the larger surfaces of the waste material that is then available.

Waste tire to oil plants have gone a long way in reducing the environmental problems of this waste material by converting them or recycling them into useful products. More related information on https://bestonpyrolysisplant.com/waste-tyre-pyrolysis-plant-cost/ here.