When a pyrolysis plant is set up, they are typically designed to work nonstop. The workers in charge of maintaining them can work around the clock. These is often referred to as continuous tire pyrolysis plant. Although there will be times where maintenance must be done, they are typically converting materials into charcoal and liquid fuel. If you have a substantial number of tires on your property, you may want to consider getting one of these pyrolysis plants for yourself. There are reasons why the continuous models are so much better. This overview will help you understand why you may need a continuous waste tyre pyrolysis plant.

How These Machines Convert Tires Into Burnable Fuel

The process of carbonization is at the heart of the pyrolysis process. Carbon-based materials can be broken down. For instance, when you are working with plastic, it is derived from fossil fuels and this can lead to producing charcoal. The same is true with rubber tires. There are literally billions of them that are lying around. For some, they believe that using these machines can be positive for the environment. Others look at this business model as a way to generate revenue. By preparing the tires, and heating them up in the pyrolysis reactor, this is how the liquid fuel and charcoal is produced. See the detailed process on this web https://tyrepyrolysisplants.net/tyre-recycling-process.html.

What Type Of Continuous Tire Pyrolysis Plant Will You Need?

Deciding on the right size of pyrolysis plant comes down to how often you believe you will use it. Those that have an unending source of rubber tires will want to choose the largest continuous model. Those that have only intermittent access to rubber tires may want to get something much smaller. You can always decide this by looking at your inventory, and what you will soon have, to make this decision.

How Do Continuous Tire Pyrolysis Plants Work?

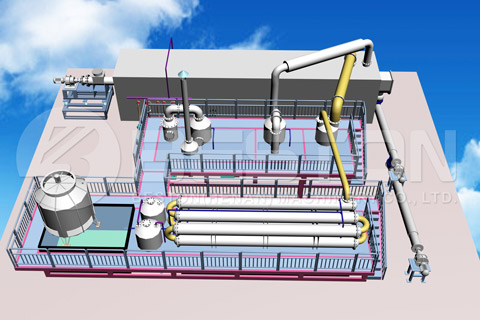

The structure of these pyrolysis plants is very similar, regardless of who the manufacturer is. It always begins with a way of breaking down the materials. The pieces of the tires must be very small. This allows the process to be much more efficient. Once this material is chipped up or ground down, it will be fed into the reactor. It is there that the oxygen is taken out, and the superheating will commence, allowing this process of carbonization to occur. There are also other components including the cyclone, gas chamber, and a place where the heat will be dispersed. The final products will be solid charcoal and liquid fuel. There is an another plan for you to see https://tyrepyrolysisplants.net/tyre-pyrolysis-plant-in-india.html.