Charcoal has been a vital commodity for centuries, used for cooking, heating, and various industrial applications. With increasing environmental concerns and a growing demand for sustainable alternatives to traditional charcoal production methods, pyrolysis has emerged as a promising solution. Pyrolysis is a process that converts organic materials into charcoal, bio-oil, and syngas through high-temperature decomposition in the absence of oxygen. This innovative approach offers numerous benefits, but is a charcoal maker machine by pyrolysis the right choice for you? In this comprehensive guide, we’ll explore the key considerations and factors to help you make an informed decision.

Understanding Pyrolysis Technology:

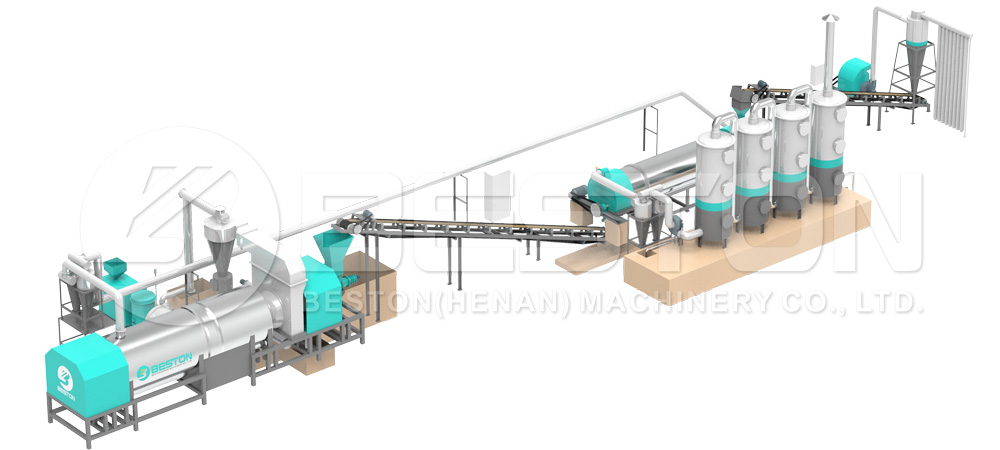

Pyrolysis technology involves heating biomass materials such as wood, agricultural residues, or organic waste in a controlled environment to break them down into their constituent elements. The absence of oxygen prevents combustion and leads to the formation of charcoal, bio-oil, and syngas. This process offers several advantages over traditional charcoal production methods, including higher efficiency, lower emissions, and the ability to utilize a variety of feedstocks.

Market Analysis:

Before venturing into any business, it’s essential to conduct a thorough market analysis to assess the demand for your product and identify potential competitors. In the case of charcoal made by pyrolysis, there is a growing demand for sustainable alternatives to conventional charcoal due to increasing environmental awareness and regulations. Additionally, pyrolysis-derived charcoal may command a premium price in niche markets such as organic agriculture or artisanal cooking.

Feasibility Study:

A feasibility study is crucial for determining the viability of a charcoal making business by bamboo charcoal machine. This study should evaluate factors such as the availability and cost of feedstock, the capital investment required for equipment and infrastructure, operational expenses, potential revenue streams, and projected profitability. Conducting a comprehensive feasibility study will help you identify potential challenges and opportunities and make informed decisions about your business.

Environmental Considerations:

One of the main advantages of pyrolysis technology is its environmental sustainability. Unlike traditional charcoal production methods, which often involve deforestation and emit harmful pollutants, pyrolysis produces charcoal with minimal emissions and can utilize renewable biomass resources. By reducing reliance on fossil fuels and mitigating deforestation, a charcoal making business by pyrolysis can contribute to environmental conservation and sustainability.

Regulatory Compliance:

Operating a charcoal making business by pyrolysis requires compliance with various regulations and permits related to environmental protection, waste management, and occupational health and safety. Depending on your location and the scale of your operation, you may need to obtain permits for air emissions, waste disposal, and land use. Ensuring regulatory compliance is essential for avoiding legal issues and maintaining the reputation and sustainability of your business.

Investment and Financing:

Starting a charcoal making business by pyrolysis requires a significant initial investment in equipment, facilities, and infrastructure. Depending on the scale of your operation, this investment can range from thousands to millions of dollars. Securing financing for your venture may involve a combination of equity, debt, grants, and subsidies. Working with financial institutions, investors, and government agencies can help you access the capital you need to launch and grow your business.

Operational Challenges:

Operating a charcoal making business by pyrolysis involves various operational challenges, including sourcing consistent quality feedstock, optimizing pyrolysis processes, managing waste products, and ensuring product quality and consistency. Additionally, pyrolysis equipment requires regular maintenance and may experience downtime due to mechanical failures or process upsets. Developing robust operational procedures and contingency plans is essential for overcoming these challenges and ensuring the smooth operation of your business.

Marketing and Distribution:

Successfully marketing and distributing your pyrolysis-derived charcoal products is essential for achieving commercial success. This may involve identifying target markets and customers, developing branding and packaging, establishing distribution channels, and implementing promotional strategies. Building relationships with retailers, wholesalers, and end-users can help you create demand for your products and generate sustainable revenue streams.

Scaling and Expansion:

As your charcoal making business by pyrolysis grows, you may consider scaling up your operation or expanding into new markets or product lines. Scaling up may involve investing in additional equipment and infrastructure, increasing production capacity, and optimizing processes for efficiency and cost-effectiveness. Expanding into new markets or product lines may require market research, product development, and strategic partnerships. Careful planning and execution are essential for ensuring the successful growth and expansion of your business.

Conclusion:

A charcoal making business by pyrolysis offers numerous opportunities for entrepreneurs interested in sustainable and environmentally friendly ventures. However, success in this industry requires careful planning, investment, and execution. By considering factors such as technology, market analysis, feasibility, environmental considerations, regulatory compliance, investment and financing, operational challenges, marketing and distribution, and scaling and expansion, you can determine whether a charcoal making business by pyrolysis is the right choice for you. This machine also is used for processing sugarcane waste. So it is also called sugarcane bagasse charcoal machine. With proper planning and execution, you can build a profitable and sustainable business that contributes to environmental conservation and meets the growing demand for sustainable charcoal products.