If you’re going to be investing in an egg tray machine, you’ll find that manual machinery is the option that’s price most affordable. In many cases, this machinery will be hundreds or even thousands of dollars cheaper than semi-automatic and automatic counterparts.

Of course, there are also some clear drawbacks to purchasing manual egg tray making machine. As the name implies, this equipment will have to be operated manually. Is investing in a manual egg tray making machine worthwhile? If that’s a question you’re trying to answer, you’ll want to ask yourself a few more questions.

What Are Your Production Goals?

Whether a manual machine will work for you will largely depend on what your production goals are. You’ll be able to produce far fewer egg cartons with a manual machine, and if your production goals are on the higher side, equipment like this may not be a good fit for you.

When you read the product description for the manual equipment that you’re considering, you should see an estimate of how many cartons you will be able to produce in an hour. It’s best to assume that you’ll be producing a number that’s slightly below that. If that number isn’t suitable for you, you’ll want to focus on some of your other options instead. Click here to know more: https://eggtraymakingmachine.net/how-to-make-egg-trays/.

What Are Your Labor Costs?

While you’ll save money buying a manual machine, these machines will require more labor to operate, which means they could wind up costing you more money over time. When calculating your total costs, you’ll want to estimate what your labor costs are likely to look like if you opt to invest in this machinery. From there, you’ll want to compare that against your labor costs if you invested in an alternative.

In some cases, you may find that it makes more financial sense to invest in semi-automatic machinery. Don’t get swept away by the low initial cost of a manual machine. In certain situations, these machines will cost you more than the alternatives over time.

What Is Your Budget?

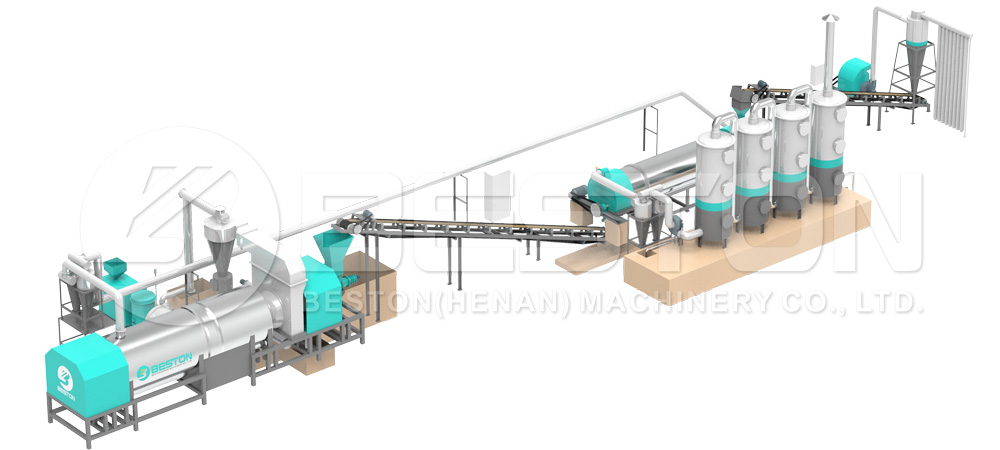

If you have a very limited budget, and you don’t think you can afford to invest in an automatic machine, a manual machine could wind up being your only option. Determine what you can reasonably afford to spend on this purchase. From there, you should look at options that are comfortably within that price range. Compare options and work to find suppliers that offer better-than-average deals. See various of paper egg tray drying line here.

In some cases, however, you may find that you’re able to stretch your budget further than you anticipated. For example, you might be able to afford a semi-automatic machine. Look at what your budget is able to buy you and try to make your purchasing decisions from there.

After asking and answering these questions, it will be easier for you to determine if it makes sense to invest in a manual egg tray machinery. No matter what you decide on, you’ll be able to make the right decision and make a purchase that you’ll feel satisfied with.